The differences of chemical composition for 309 and 309S stainless steel

Grade

C

(%)

Si

(%)

Mn

(%)

P

(%)

S

(%)

Cr

(%)

Ni

(%)

N

(%)

Cu

(%)

309

≤0.25

≤1.0

≤2.0

≤0.045

---

22.0-24.0

12.0-15.0

---

---

309S

≤0.08

≤1.0

≤2.0

≤0.045

≤0.03

22.0-24.0

12.0-15.0

---

---

The differences of Mechanical property for 309 309S stainless steel

|

Grade |

tensile strength Mpa |

Yield Strength Mpa |

Elongation (%) |

rate of reduction in area (%) |

Density (g/cm3) |

|

309 |

≥475 |

≥180 |

≥40 |

≥50 |

7.98 |

|

309S |

≥515 |

≥205 |

≥40 |

≥50 |

7.98 |

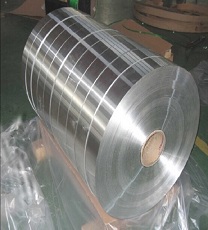

Specifications for 309/309S stainless steel

|

Technical |

Thickness |

Width |

Finish |

Origin |

|

Cold rolled |

0.8mm-3.0mm |

Standard width in China:1000mm 1219mm 1500mm Special width:can be ordered |

2B / No.4 / HL / BA / Mirror etc |

TISCO / ZPSS etc |

|

Hot rolled |

3.0mm-80.0mm |

Standard width in China:1219mm 1500mm 2000mm Specail width:can be ordered |

No.1 |

TISCO / ZPSS etc |

Applications for 309/309S stainless steel

309 309S stainless steel is mainly used for easy cutting and high surface finish.

And 309 309S stainless steel with corrosion resistance, excellent high temperature performance, it can withstand 980 C high temperature.So it is widely used in energy (nuclear power, thermal power, fuel cell), industrial furnace, heating furnace, incinerator, chemical, petrochemical and other fields.

Standards for 309/309S stainless steel

|

Grade |

GB/T 1220-2007 |

ASTM |

DIN |

JIS |

KS |

|

309 |

16Cr23Ni13 |

309 |

1.4828 |

SUS309 |

STS309 |

|

309S |

06Cr23Ni13 |

309S |

1.4833 |

SUS309S |

STS309S |

The weight calculation method for 309/309S stainless steel

Weight(KG/PC)=thickness(mm) x width(Meter) x length(Meter) x 7.98

Small knowledge for 309/309S stainless steel

The corresponding 309S China brand is 0Cr23Ni13, American Standard S30908 (AISI, ASTM) properties and uses: corrosion resistance and heat resistance are better than 0Cr19Ni9. 309 compared with 309S, no sulfur content of S.

309S is a variant of the 309 stainless steel with low carbon content, used for welding. The lower carbon content reduces the amount of carbides precipitated in the heat affected zone near the weld, and the precipitation of carbides may lead to intergranular corrosion (corrosion) of stainless steel in some environments.

- *

- *